Below is our recent interview with Gretta Perlmutter, Customer Success Manager at nano3Dprint:

Q: Could you provide our readers with a brief introduction to nano3Dprint?

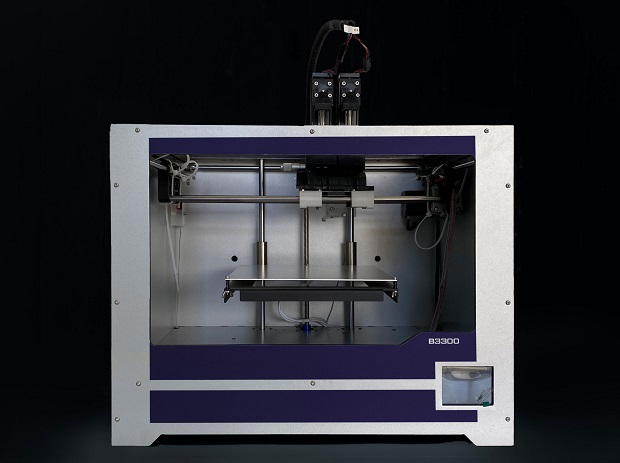

A:nano3Dprint offers next-generation additive manufacturing solutions that enable the printing of fully-realized electronic devices with seamless integration of micro-to-nanoscale materials. Our company is composed of a team of scientists and engineers who are committed to crafting the most innovative technology available. We’ve made it possible for our customers to produce fully 3D functional electronics with embedded circuitry right from their desktops. For example, our new B3300 Dual-Dispensing 3D printer can print a flexible wearable out of silicone with wires and sensors made from silver nanoparticle ink printed right into it. Our direct-write technology can be used to invent, design, test, research and perform low-volume manufacturing. It empowers users to expand their fields of innovation.

Q: You’ve recently announced the launch of its B3300 Dual-Dispensing 3D Printer; Any highlights on your announcement?

A: Yes! We’re excited, because the B3300 produces objects like medical devices, wearables, batteries, solar and other functional electronics with embedded circuitry. This desktop 3D printer can print functional pastes and highly conductive inks that allow electronics to be made in one process. The B3300’s unique, proprietary dual-material dispensing system can print two different materials together to build combined material prints. It expands users’ range of printing materials – from gold and silver to UV-curable polymers and silicone. Full 3D patterns may be printed onto any substrate and combine materials. A wide viscosity range (1mPa·s to 54000 mPa·s) enables the use of highly conductive inks in the B3300. Functional inks and pastes may be printed down to 8 mils (0.20mm) trace width. The printer can also quickly print thick layers (500 microns) with high-viscosity multi-materials in a single pass, resulting in turnkey electronic items ready for use. Finally, we’ve made this technology more accessible than ever – it’s available for general consumer use at a significantly lower cost of ownership than any other direct-write technology.

Recommended: Metazoa Builds A Suite Of Products That Helps Administrators Manage Complex Salesforce Organizations

Recommended: Metazoa Builds A Suite Of Products That Helps Administrators Manage Complex Salesforce Organizations

Q: Can you give us more insights into your additive manufacturing solutions?

A: nano3Dprint’s technology is ideal for research and development and prototyping; and low-volume manufacturing for the medical, agriculture, solar industries and general consumer electronics. Our customers can 3D print almost any material onto virtually any substrate and even make the strongest 3D prints available with composite materials. For example, users can print a layer of plastic, followed by a layer of “glue,” and so on, resulting in composite structures that are tougher than ever before. Furthermore, our new B3300 Dual-Dispensing 3D Printer allows for new combinations of materials that have been difficult to print together – like silicone and gold or dielectrics with semiconductors – to now easily be printed in combination. This opens many doors for professionals to excel in their careers – the sky is the limit in terms of what they can quickly produce from their desktops.

Q: What can we expect from your company in the next 6 months? What are your plans?

A: Next up is the launch of our much-anticipated high-resolution D4200S 3D printer. We’ve leveraged our scanning probe nanotechnology product and system knowledge to produce this micro-to-nanoscale materials printer for printed electronics, prototyping, R&D, and industrial applications. It’s ideal for flexible electronics, maskless lithography, mask repair, bioprinting, tissue engineering and beyond. The print head accommodates various print materials, including Au, Ag, Cu, polymers, metallic oxides, dielectrics, organic compounds, photosensitive polymers and more. The high-speed microdeposition mode dispenses functional materials with feature sizes from 5 μm to 400 μm. The nanodeposition mode prints feature sizes from 20 nm to 250 μm. The printer allows researchers, scientists, designers, inventors and engineers to print at the micro and nanoscale levels with ease. It will open doors to new inventions and discoveries.

Recommended: Hula Data Network Engineering

Recommended: Hula Data Network Engineering

Q: What is the best thing about your current electronics printer lineup?

A: Our A220 and B3300 direct-write systems allow users to print a wide range of multi-materials side-by-side, empowering them to 3D print electronics housing as well as the internal circuitry. We always say, “Don’t add wires, print them!” Embedding the connections between components allows for more conformal and complex features. Additionally, depending on the printer, our customers can use a wide range of print materials from inks with sensing capabilities, dielectrics and semiconducting properties to functional pastes to FDM, UV-curable silicone and other new and traditional materials. They can produce wearables with embedded conductors, cell phone parts with tiny antennas or electronic devices with built-in sensors. Our printers can incorporate strain gauges, heaters, complex antenna geometries and optical components in a 3D print. Finally, our direct-write technology is compatible with most Slicer or CAD software, providing our customers with choice and freedom. Learn more about nano3Dprint’s A2200 3D printer.