Below is our recent interview with Etienne Lacroix, CEO and Founder of Vention:

Q: Could you provide our readers with a brief introduction to Vention?

A: Many refer to our products as industrial lego. That makes me smile, because our passion for machine design originates from childhoods spent playing and building things.

Currently, the process of designing, building and assembling an industrial machine is long, costly, and unnecessarily painful. Yet with today’s technology, Vention has developed a simple and efficient machine design process that anyone can leverage to get a custom industrial machine designed, assembled, and ready to operate in a matter of days.

On vention.io we offer an intuitive CAD system anyone can access for free in their web browser. It integrates a comprehensive list of parts—all of which fit seamlessly and effortlessly together, thanks to Vention’s modular hardware system. This enables a huge shift in terms of design simplicity and time: it’s 10x faster to design on the Vention platform than a traditional CAD.

Once you’ve completed your design and placed an order, we ship all the parts the next day. From there, the machine is ready to be assembled using just one tool and one type of screw. For automated solutions, we provide a code-free environment for the creation of the entire automation logic of the machine; that makes it incredibly simple to get going.

You now have a machine ready to operate, except you got there in 3-4 days instead of 3-4 months—and at a fraction of the cost.

Vention enables anyone to design specifically for their needs. We see all sorts of applications, such as 7th-axis range extenders for robots, inspection cells, assembly jigs, workstations and industrial furniture, palletizers, automated conveyors, 3-axis CNC machines, and many more.

Recommended: All-In-One Social Shopping App Passfeed Helps Almost A Million People Every Month Find Deals And Savings

Recommended: All-In-One Social Shopping App Passfeed Helps Almost A Million People Every Month Find Deals And Savings

Q: Can you give us any insights into MachineLogic?

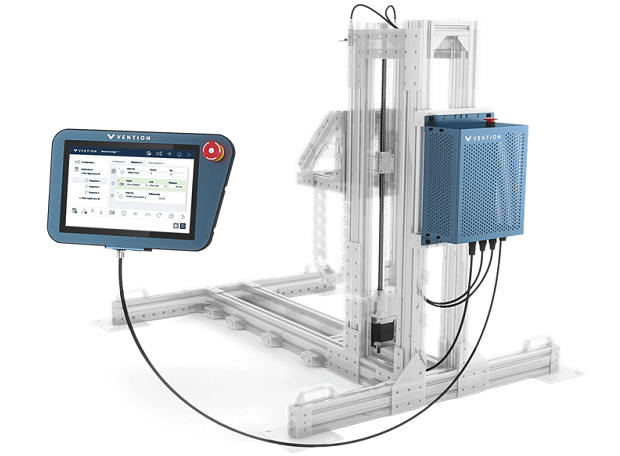

A: MachineLogic simplifies industrial automation. It’s a code-free visual sequence editor that empowers manufacturing professionals to automate their equipment in an intuitive cloud-based and local environment.

You can use MachineLogic in the Vention CAD to simulate and visualize your automation sequence while you’re designing your machine. You can also use MachineLogic from the Vention pendant (a touch-screen tablet linked to our MotionController that controls all the motors and sensors in your machine). Of course, you can upload your sequences from your computer to the pendant easily.

Q: What’s so special about the MachineLogic feature?

A: Every system and product we develop at Vention aims to improve accessibility, simplicity, and efficiency. This is especially critical when working with automated machines, as it can be intimidating if you have little automation experience or do not have a technical background. In traditional industrial automation, every piece of equipment typically uses its own custom software or language. This means lots of software development and lots of proprietary languages to learn.

The big challenge was to make MachineLogic simple enough that anyone could use it. To accomplish this, we made MachineLogic a code-less interface, integrated all the automation components under one solution, and made it as user-friendly as possible. Working with MachineLogic ultimately feels simple, easy, and intuitive.

Q: You’ve recently launched a certified system integrator program to support large-scale factory automation projects; could you tell us more about that?

A: We have a growing number of clients with quite large and complex projects. These clients appreciate saving money and time with Vention, but given the importance and scale of their automation projects, they also want to have hands-on support to oversee the design, installation, and calibration of their automated machines.

We have partnered with experienced and trusted integrators in various regions to serve this need. All our integrators get specific Vention training and become true experts on the Vention platform.

Recommended: First Page Digital – A Full-Service Digital Marketing Agency, With Focus On SEO, And Paid Advertising

Recommended: First Page Digital – A Full-Service Digital Marketing Agency, With Focus On SEO, And Paid Advertising

Q: What are some of the specific use cases or scenarios you can share on how consumers can leverage Vention?

A: We serve both large institutions and smaller shops. Our larger clients tend to appreciate how quickly they can get a new machine—one they often urgently need to keep production running. Our current clients include large and small clients in the robotics, aerospace and automotive industries

Our smaller clients are often considering automation, but haven’t gone all the way yet. They appreciate the simplicity and cost-savings of designing and building with Vention.

The use cases vary widely from one another. Anyone can share their designs publicly in our design library and gallery. Take a look to get a better idea of the types of projects Vention is working on.

As for specific cases, we recently worked with Foothills Industries, a surgical drape manufacturing and service company in western North Carolina, to design and fabricate a custom textile-cutting machine.

Q: What are your plans for the future?

A: Vention only launched three years ago, and recently received a significant investment from Bain Capital Ventures. With this influx in capital, we’ll keep improving our CAD experience, adding more components to our parts library, and enhancing our automation solutions. Lastly, we plan to continue to scale aggressively as more people learn how we are simplifying machine design for everyone.