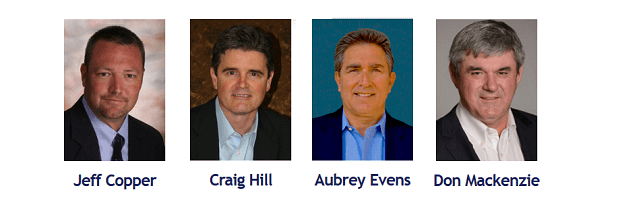

Below is our recent interview with Don Mackenzie, EVP & SAP Practice Lead at C&A Technology:

Q: First, could you provide our readers with a brief introduction to C&A Technology?

Don Mackenzie: C&A Technology’s (which we call CAT for short) value proposition is that we bring together SAP and JD Edwards professionals who have anywhere from 15-25+ years of senior-level ERP product knowledge experience, as well as are experts in our core industries that include Food Processing.

At CAT, our strong belief is that we best service our customers by aligning business systems with their business strategies enabled by technologies, such as SAP. While our JDE practice started in 2011, our SAP practice is relatively new and we’re focusing on the industries that we have deep knowledge and experience, such as Food.

Q: Tell us more about your SAP practice and why starting it was so strategic for CAT?

Don Mackenzie: Our SAP consulting practice extends CAT’s services and solutions to a new base of ERP users. We’re an SAP partner and decided to partner with SAP because of their best-in-class software that is key to industries such as Food Processing.

Personally, I have 15 years of direct SAP experience in sales and solution architecture, as well as 16 years of JDE experience in sales consulting and solution architect roles. From a Food Processing perspective, I specialized in this industry during my time with both SAP and JD Edwards. Having both perspectives, I can offer our customers the unique ability to migrate from JDE to SAP – or vice versa.

Q: What areas of the Food Processing industry are you initially focused on?

Don Mackenzie: In the food industry, our consultants bring over 20 years of SAP and food processing expertise in Dairy, Meat Processing, Eggs, Bakery, Coffee, Consumer Packaged Food, Foodservice Distribution, and Integrated Agriculture. We’re initially focusing on perishables (such as Dairy, Meat, and Eggs) because there are common business issues across all three sub-segments, such as short shelf life and costing.

Q: How does CAT help food processers with their SAP systems?

Don Mackenzie: We can help optimize older SAP systems for today’s food industry trends and requirements to maximize product quality, customer service, and profitability. One of the greatest challenges for the Food Industry in general is adjusting SAP systems for today’s market conditions that demand greater granularity in data analysis. Examples where this need for granularity may surface are in:

• Industry-relevant costing methods like actual costing (Dairy, Agricultural processing),

• Food traceability that requires a high level of granularity to mitigate false positives in high cost incidents, like recalls

• Production and related planning/scheduling performance to support compliance, e.g. allergen sequencing to avoid contamination and the pursuit of compliance/regulation

• Supply chain processes, integration of third-party logistics operations, as well as engagement of trending best practices like IIoT within logistics to track Critical Controls during logistics execution (e.g. shipment temperature).

The Dairy industry presents one of the clearest examples of high perishability in raw milk that has to be sold or processed within hours, or run the risk of losing its value entirely – but also tracing the process from raw milk through its components into salable products (packaged fluid, skim, butterfat, evaporated, powder, cream, butter, yogurt, ice cream and all the others). While updating and optimizing our clients’ SAP systems, we thoroughly test, manage change and move the updated solution into production within preferred timing to minimize business disruption.

Q: What do you think are the greatest challenges today within the Food Processing industry for those running SAP?

Don Mackenzie: The decision to stay where you are or to change to SAP’s latest S/4HANA solution. You may see this as a typical technology sales response, but let’s examine this a little more. Staying where you are probably means you are risk averse. Perhaps the current system is performing quite well, and the memory of the pain of implementation is still a little too fresh in your minds.

The concern with this position is that the market is moving, digitization is top of mind to those wanting to capture any new opportunity and maximize value for the company. If demand shifts to new innovations or new (global) markets, you want to see those quickly and transform process quickly to adjust to the demands of the change. SAP’s S/4HANA and the in-memory processing capability addresses the needs of this new Digital Enterprise.

It takes both Discovery and Preparation to set a migration process on the correct course. Decisions between Greenfield and Brownfield depend heavily on an understanding of the facts about your existing SAP landscape, which points specifically to understanding the technical enhancements that have been made to your system. Also, any dissatisfaction with current practices in your current system may provide the opportunity to review and redo some of your processes, and this may sway the decision to Greenfield versus Brownfield. There is no doubt that complexity drives duration, but a lack of planning also adds unnecessary time and cost to the process, which should be planned in weeks, not months or years.

Q: What are the greatest opportunities for food processers running SAP?

Don Mackenzie: I mentioned in-memory processing, but let’s dig into this a bit. SAP S/4HANA customer stories are beginning to emerge where a demand plan was completely altered, turned upside down if you will, due to a substantial shift in the ultimate end customer’s business. It took minutes to transform all procurement and manufacturing processes to the new plan. SAP’s in-memory technology is active across the entire S/4HANA solution, not just in convenient pockets of functionality where intense processing may be more likely. So when we shift our focus back to the incredible breadth in business process support for all Consumer Products companies today that SAP has provided for decades, this comes back to life in the platform that is incredibly fast.

This business process competence has been perfected over decades of focus on industry solutions, including all Consumer Products segments, but specifically in Food Processing and Distribution. The In-Memory capability of the SAP HANA platform, and the native integration between SAP HANA and SAP S/4HANA provides a real opportunity for true real-time computing. Planning latency is shortened to minutes at the most from the hours of the past. Trends in data that enable an opportunity to dramatically curtail cost can be actioned everywhere in the solution, but perhaps Food Safety is the most understandable of these, especially when it comes to the business risk associated with quality events and recall processes. The standard needs of a Food Processor today can address allergen-attentive planning cycles quickly and efficiently without the headaches associated with physical separation and monitoring needed in the past. Plan it properly, in-memory, get the right plan onto the plant floor for execution without any latency, and focus on what really matters – building your brand and growing your business.

Beyond the technical capability to process in-memory and the ability to run business processes very quickly, another critical solution element has surfaced in the modern SAP solution world. SAP HANA’s in-memory capability has enabled the merging of analytics and transaction processing into one platform that now enables reporting against processes executed seconds previously in their entirety. This capability addresses operational reporting using Core Data Services embedded in the S/4HANA (ERP) solution but can also be extended to reach more robust data visualization solutions from the SAP Solutions portfolio.

Q: What unique advantage does CAT bring to the Food Processing industry?

Don Mackenzie: CAT’s approach will help food processers isolate the business areas that are the most applicable to them (e.g. Traceability, Profitability Analysis, Process Integration) and link all business processes that need to be adjusted and improved for success. The intent is to focus our work on a narrow definition of scope and isolate the best potential value at a low cost.