Below is our recent interview with John Joseph, Co-Founder & CEO at Datanomix:

Q: Could you provide our readers with a brief introduction to your company?

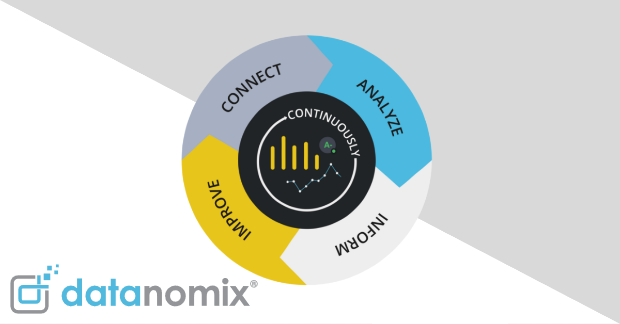

A: Datanomix is a software company aimed at empowering precision manufacturers through advanced data analytics. Datanomix offers a next-gen production monitoring solution that shows manufacturers how their CNC machines are performing in real time, while offering deep insights into overall factory performance over time. And we do this all without requiring any operator input, unlike first-gen production monitoring solutions.

Instead, we use machine learning to analyze the data coming directly from the machines to first benchmark performance, and then analyze it to provide actionable insights that allow production supervisors to deploy their best personnel to the jobs that need attention. And over time, we unveil trends that help management make better decisions around job quoting, capital expenditures, hiring, operator training and overall personnel management.

Q: Any highlights on your recent announcement?

A: The two big takeaways from our recent announcement is that business is booming and our customers love us! We’ve tripled revenue, customers, and employees as the industry has embraced our “no operator input” approach to intelligent production monitoring. The most satisfying statistic is that we have a 100% retention rate for customers, with most of them significantly expanding their Datanomix footprint within months of the initial install.

We also have a number of customers who are expanding Datanomix throughout their entire organization, including a few multi-factory upgrades at locations across the United States. In several cases we installed our product at one of ten facilities within a PE owned portfolio, and then they expanded to every facility and a request to prepare for all future acquisitions.

From a product perspective, we are innovating the product on an ongoing basis based on the feedback from our customers. All of our new features are designed to reduce the work our customers have to do in half.

Recommended: Data 360 Helps You Grow And Optimize Your Business Using AI, Machine Learning And Big Datat

Recommended: Data 360 Helps You Grow And Optimize Your Business Using AI, Machine Learning And Big Datat

Q: Can you give us more insights into your offering?

A: The Datanomix platform hooks directly to the controller on our customers’ CNC machines, reading the data in real time as parts are produced. We take a look at their operations on a per-job and per-machine basis, gathering metrics and driving insights at that level. When you know exactly what’s happening on the shop floor in real time, and the current status of all the running jobs are displayed on large-screen TVs throughout the shop, the entire team can rally around production every day.

With Datanomix, your best resources gravitate towards the jobs that need attention, machine operators can more easily manage multiple machines, and opportunities for training and process improvements become apparent as more data is gathered and patterns of production are unveiled. Datanomix is like a virtual window into your factory’s performance.

Q: What can we expect from your company in the next 6 months? What are your plans?

A: As we ramp up, and we get more exposure to more customers, machines, and parts, we will continue to develop the Datanomix platform. Many of our innovations – Quote Calibration, the Coffee Cup Report, and the Continuous Improvement Hub – have come directly from feedback and work with our customers. This will continue to drive further enhancements to the product.

In addition, we are adding additional sources of data to enrich our models so we can extend the reach of Datanomix. Our recent announcement with Caron Engineering is a great example. With Caron, we get deeper insights into tool paths and cutting performance, providing a rich repository of data that will help us deliver new functionality around tool performance and machine maintenance. The insights from tooling analysis and optimization are the major cost drivers in profit calculations for our customers. When these variables are optimized for each part produced, tides rise for the entire corporation.

Recommended: Publishing House Vibrant Publishers Focuses On High Quality Guide Books For IT, Management Professionals And Graduate Studentst

Recommended: Publishing House Vibrant Publishers Focuses On High Quality Guide Books For IT, Management Professionals And Graduate Studentst

Q: What is the best thing about your company that people might not know about?

A: We are proud to be working with American manufacturers at a time of great change in the industry. As manufacturing continues to reshore to combat supply chain issues and in some cases, a need for higher precision and quality control, Datanomix is helping US manufacturers embrace digital transformation to remain competitive on a worldwide stage. Datanomix is uniquely positioned to help precision manufacturers with unattended operations by monitoring performance for lights-out shifts.