* – This article has been archived and is no longer updated by our editorial team –

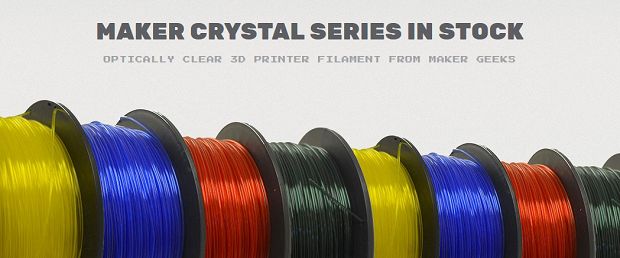

MakerGeeks Manufacturing, Inc. (Maker Geeks) is a plastics manufacturer located in Springfield, MO with a specialty in producing high tolerance 3D printer filament (mono-filament) in large scale batches.

Below is our intervew with Joshua Smith, the Founder & CEO at MakerGeeks.com:

Q: Could you provide our readers with a brief introduction to Maker Geeks Manufacturing?

A: Maker Geeks can blend and produce over 1,500,000lbs of plastic filament each year with a maximum tolerance variation of less than 00.05mm over the life of the product run. Maker Geeks has been very blessed to find, hire and cultivate a team here at the Springfield plant of retired engineers and plastics specialist to run our lines and produce not only the industry standard 3D filaments such as ABS and PLA but industry first composite blends of plastics like our Raptor PLA and our engineering grade flexible TPU++ resins. Maker Geeks is able to take an idea from conception, to testing, to mass scale production in lightening speed and have a finished retail product ready for market in many cases under 14-21 days since we can process the required functions in house. Founder and CEO of Maker Geeks Joshua b Smith has been in the manufacturing industry for over 17 years and brings his expertise to an already highly specialized team here at the Springfield, MO Maker Geeks plant. Maker Geeks is one if not the only high-speed, large volume 3D Printer Filament manufacturer on US soil to date.

Recommended: Are You Looking For A New Hoverboard In 2018? HX Phantom Review

Recommended: Are You Looking For A New Hoverboard In 2018? HX Phantom Review

Q: How did the idea behind Maker Geeks come about?

A: MakerGeeks.com was born out of a hobby that got way out of hand. I have always been interested in building and making even as a small child, whether it was taking the door knob off the family home at age 5 to find out how it worked or devouring the newest BASIC programming guide in the back of my Boys Life magazine to the epic plans of robots and lasers that overflowed my tree house fort work-bench; yup… you could say I was bit with the MAKE bug early and often!

However, in 2009 I got hooked on Arduino programming and building and flying home-made quad-copters. On a forum that I was a member of for the Aero-Quad group I met some great people and one of them got me interested in 3D Printing – we talked a lot about what makes a good 3D Printer and over the months I decided to make a Mendel90 RepRap machine from scratch. I wanted to source all my own parts (well back then you had to, there was no MakerGeeks or anyone else selling these parts here in the USA) so I could build the machine from the ground up and have some ownership in the design. After about 6 months of building and tinkering I was HOOKED, OK… beyond hooked actually and I wanted to be able to share this new passion with others – and to make it easier to find these parts, printers, advice and filament – remember, when MakerGeeks started there really was no US based option for 3D printing save a few small hacker-space shops that also sold their wares online.

We launhced Maker Filament®, our very own in-house 3D Printing Filament; MakerGeeks is one of the first and only companies to solely focus on 3D printing filament manufacturing in the USA.

While there are a few other USA extrusion houses of mono-filament they often operate in small and expensive batches or do so as a side line business in co-junction with their profile or sheet extrusion offerings. MakerGeeks.com operates 4 large scale, high-speed, high-tolerance extruders right here on US soil and it’s our goal to remove the need to order 3D Printer Filament from China (nearly all 3D printer 3D printer filament in the past 10 years started its life in China; even the really good stuff!).

Q: What advantage does Maker Geeks have over its competitors?

A: Maker Geeks’ size and scale is our best advantage in that being able to run larger batches of filament we can keep cost and waste down. Most of our competitors are smaller home brew type companies that might be making 20-50kg a day and selling online – Maker Geeks is able to make around 2,000kg per day which significantly brings our cost down. Also, most if not all our competition are using home-made extrusion lines so the tolerances aren’t as good as something that would come off a commercially built line with modern systems in place. To this end in just the 3 short years Maker Geeks has been manufacturing it’s own 3D filament we have already seen 4 competitors go out of business all the while, seeing Maker Geeks have 100% year over year growth – each of these competitors have approached us to buy their companies so we do have some special insight into the sate of the manufacturing methods that most are using.

Recommended: Cygnetise Helps Companies Easily Manage Authorized Signatory Lists Using Blockchain Technology

Recommended: Cygnetise Helps Companies Easily Manage Authorized Signatory Lists Using Blockchain Technology

Q: What are your plans for next four months?

A: We have just installed another production line to increase our volume as we find it hard to keep up still so the next 3-4 months will be dedicated to training staff and management as we increase our throughput we are also in talks with Amazon Business in bringing a line of 3D printer filament out for sale on Amazon Prime which we are very excited about. Longer term we are already shopping for another building to move to as we have quickly outgrown our 8,000sq/ft main production floor so a move to a larger building will be required before to much longer. It’s a very exciting time for Maker Geeks that’s for sure.

Q: More generally, how do you see the 3D printer landscape developing, and where do you place yourself in the industry?

A: The 3D printing market is growing so much right now it’s hard to keep up with what’s new… many trade journals put the material side of the things, the plastics to grow from a worldwide market of $50million to over $5 billion annually by 2025 so I think with that level of growth we are just at the tip of the iceberg. We are excited to be leading that push to bringing manufacturing to the US in an industry that is dominated by Chinese companies and I think with a focus on quality and expansion we’ll be in the prime place to capitalize on this explosive growth.